Front wheel bearings - how to guide.

Tools needed -

- new bearings (LM 3008 49 inner/LM 3008 11 outer)

- 19mm socket

- 17mm spanner/socket

- 14mm spanner/socket

- 12mm socket/spanner

- B.F.H.

- Flat bladed screw diver

- Grease (silicone cv)

- Also could be useful - Circlip pliers and 10mm spanner/socket (if you still have the circlip on the axle stub)

- Bearing

- Short length of scaffold tube the same circumference as the inner collar of the bearing

- Cigarettes

- Beer

- Top-Tunez

- Balmy Mediterranean sunshine

First find the most inconvenient place you can think of to work, I chose the hospital's car park.

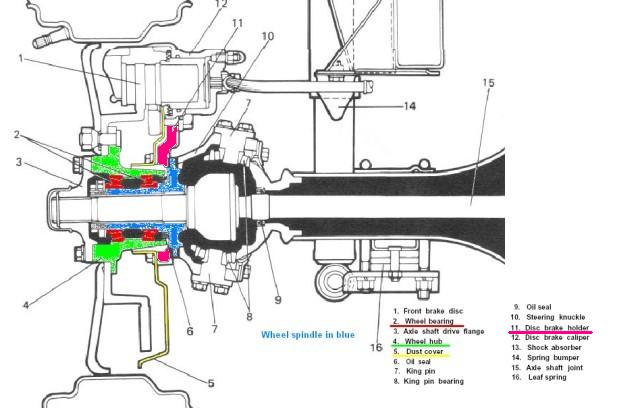

Quick over view of all the gubbins -

And we're under starters orders................ GO! Wheel off. Brake caliper and carrier off - (Good time to re-grease the caliper guide bolts)

Free wheeling hub off (If you still have the circlip on the axle stub you will have to undo the x6 10mm bolts on the hub face, remove the circlip and then undo the x6 12mm bolts holding the FWH onto the wheel hub) -

Unfold the tabs on the locking washer and remove the two big nuts and washer from the wheel spindle. The first (outermost) bearing should be behind them -

Pull off the wheel hub from the spindle. If the outer bearing race has disintegrated then it should come off easily. If this bearing is still intact then the bearings internal collar has to be slid along the length of the wheel spindle which can be problematic. You can try to 'destroy' the bearing race where it is, or use a puller against one of the large nuts (after putting it back onto the spindle) and the protruding half axle stub to pull the whole hub along the spindle thus moving the bearing forwards. If the bearing has totally "gone south" (first technical term) then only the internal collar will be on the wheel spindle so the wheel hub can be pulled off over it. You should now be left with the wheel hub in your hands with the external collars of both bearings still stuck in it - (Now is a good time to check that all the bolts for the wheel nuts are sitting properly (red circle)....)

....... and the wheel spindle with axle running through it still attached to the axle with the internal collar (and possibly the bearing race) of the inner bearing still on it -

Undo the four bolts holding the brake disc shield, brake caliper mount and the wheel spindle to the axle "knuckle" and remove the brake disc shield and caliper mount so you can get at the bearing collar still stuck there. Reattach the wheel spindle with the four bolts so the whole half axle doesn't come out and gently tap off the collar with the B.F.H. and screw driver (spinning the collar around the spindle is usually a good way to get it moving) -

Remove all the shrapnel from inside spending a short amount of time examining it's beauty and cursing it to high heaven.

IMPORTANT NOTE for all zook owners, any front wheel bearing damage was probably caused by This email address is being protected from spambots. You need JavaScript enabled to view it. (all hail the f#*!ing admins) as he is an evil and destructive man. He can sabotage my zook from 3,000 miles away just by using the power of his mind -

After giving everything a good clean, gently tap the new external collars into the wheel hub, one each side with the "slopey part" (technical term) pointing outwards on both sides i.e. in opposite directions, fat side towards the center of the hub, "pointy side" (another technical term) pointing away from the hub, etc. etc.. You can use one of the old external collars to 'bash' against to prevent damage -

Refit the brake caliper mount. Next, gently tap the first bearing onto the wheel spindle, slopey side pointing out. Use the old bearing's internal collar to whack against to prevent damage. If not already done refit disc brake cover -

Add grease then slide on the wheel hub as far as it will go. Grease up the second (outer) new bearing and slide it onto the wheel spindle slopey side in, gently taping it as with the first bearing until it sits against it's internal collar in the hub -

Spin the hub around a bit and add more grease as needed. Put on the first big nut and tighten it up against the bearing using the B.F.H. and screw driver (some have a regular washer between the bearing and nut but I've never come across one installed yet....) until the bearing is pulled all the way into it's collar and no large "side-to-sidey" (yet another technical term) play is felt in the hub - a millimeter or two is OK as this is the natural movement between the bearing race and collar ("uppy-downey" play could be related to king pin problems, my next post to be done when-ever). Slide on the locking washer and bend half the tabs in over the inside nut. Put the second big nut on the same way as the first and bend the remaining tabs out over it. Check for play and spin again, tightening (or loosening) the nuts as/if needed. Brake disc back on. Free wheeling hub back on. Brake calliper gubbins back on. Wheel back on. Pump brake peddle a few times to re pressurise the piston. Go for a spin making left and right hand turns. Jack up wheel and check (again) for play - adjust if needed (FWH off, big nuts tightened). Open beer. Drink beer. Clean up. Go home. Drink more beer.

Credits

This Article was written by Simon Owen

![0610_4wd_01z+suzuki_samurai+group_of_suzukis[1274].jpg](/images/gallery/favourites/0610_4wd_01z+suzuki_samurai+group_of_suzukis[1274].jpg)

![fenderfrt6_SJ-1[376].jpg](/images/gallery/favourites/fenderfrt6_SJ-1[376].jpg)