Both the Suzuki SJ410, and the SJ413, are fitted with a mechanically operated fuel pump.

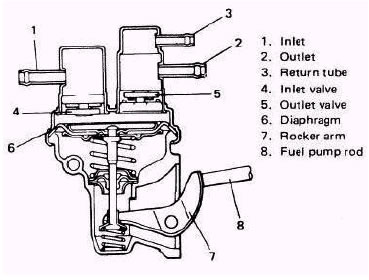

A diaphragm in the fuel pump is actuated by a cam on the camshaft, through a fuel pump rod. A rocker arm in contact with the fuel pump rod then moves the diaphragm up and down, thus pumping fuel to the carburettor.

A fuel return circuit is built into the fuel pump to avoid "vapour lock". When the float chamber is full, pressure will build up on the outlet side of the pump. This pressure will cause the excess fuel to flow through the return hose back into the fuel tank.

As long as the engine runs, fuel will flow through the pump, keeping the pump and fuel cool.

Diagnosing the problem...

There are a number of signs that the fuel pump is begining to deteriorate and break down.

- Engine noise

- You may notice the engine noise getting progressively louder. This is due to the fuel mixing with the oil in the engine.

- Oil condition

- When you check engine oil levels, you may notice you have more oil, and the oil will appear thinner due to it being mixed with fuel.

- Loss of power

- As the fuel pump deteriorates, insufficient fuel is pumped to the carburettor, resulting in a noticable loss of power, especially under hard acceleration. accelaration.

- Inconsistent idle speed

- As the pump fails, fuel will be pumped erratically into the carburettor, resulting in the float chamber being filled to different levels. This results in fuel starvation at times.

Removal of the old pump...

In the interests of Health and Safety, begin by disconnecting the negative terminal of the battery. Remove the fuel filler cap to vent the fuel tank vacuum. Then replace the filler cap.

Begin by removing the distributor cap to give yourself more room to work.

Now, disconnect the fuel inlet, outlet, and return hoses by loosening the hose clamps and pulling off the pipes using a twisting motion. The fuel pump is held in place by two nuts. Using a 12mm socket spanner, loosen these nuts, and pull off the pump.

Once the pump is off, clean the area with an old rag, and then using a pair of long-nose pliers, gently pull ot the fuel pump rod.

Check the fuel pump rod for excess wear, and replace if necessary. If the fuel pump push rod does need to be replaced, coat the new one with a thin layer of clean oil prior to installation.

Installation...

After making sure everything is clean, fit a new gasket, and mount the new fuel pump onto the mounting bolts. Slip on the spring washers, and then screw on and tighten the bolts.

Connect all the fuel lines, and re-fit the distributor cap. Start the engine and check to see that there are no fuel leaks before moving onto the next job:- replacing the diluted engine oil.

![0610_4wd_01z+suzuki_samurai+group_of_suzukis[1274].jpg](/images/gallery/favourites/0610_4wd_01z+suzuki_samurai+group_of_suzukis[1274].jpg)

![fenderfrt6_SJ-1[376].jpg](/images/gallery/favourites/fenderfrt6_SJ-1[376].jpg)