First, take one slightly shop soiled SU HIF44.

Ignore the muck, the throttle & choke spindles were a nice fit with no detectable sideways slope.

Give it a really good clean up with petrol or carb cleaner and a tooth/paint brush.

I drill a new hole for the vacuum take off point to breakout on the air filter side of the brass butterfly and blank off the old take off point.

Strip it right down to individual components and rebuild with new gaskets/seals as appropriate. I got mine from Burlen Fuel Systems www.burlen.co.uk

If building for a 1300 engine a BDL needle works well, if its for a 1600 Vitara, then a BFM is recommended. I've rebuilt mine with a yellow spring, which is slightly stronger than the standard red spring.

New rubber seal on the float chamber, these tend to harden with age and not worth rebuilding with an old one as it will probably weep at the best.

Damper, needle/bushing assembly

Damper, spring, carb assembly

Don't forget the C shaped spring clip if you have an SU with bearing damper piston

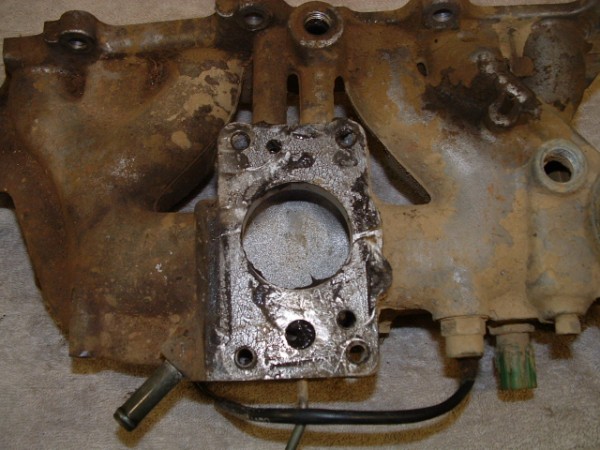

Preparing the Manifold

Standard 1300 manifold (cutting out the 2 holes)

his manifold is a 1300 single point injection one

Cut out the manifold to suit the single inlet of the SU (1600 8v Vitara manifold)

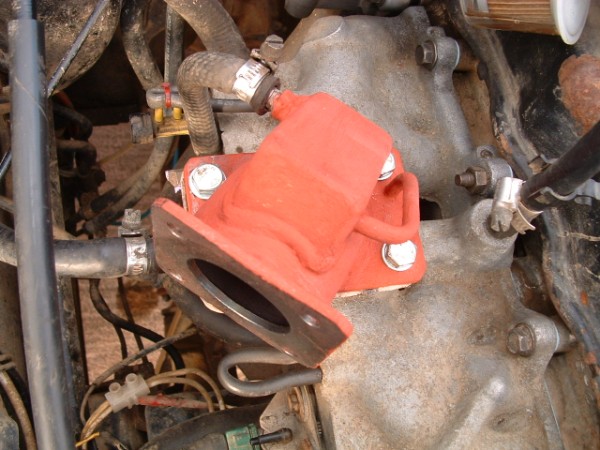

Making the Adapter Plates

Here is where I detract from the normal 'adapter plate'

On my Vit manifold there is a waterway that is used to flow coolant from the manifold up around the original Aisin carb and back out via a small rubber tube back to the water pump (it's pretty much the same for the 1300).

It's circled in red on the pic of the Vit manifold above.

So, knowing the SU carb icing issues, I decided to make a little water jacket around the adapter. Feed it from the manifold/adapter and back out via the original tubing.

I don't think I've ever seen an adapter made in quite this way before.

I've seen a jacket fed with 2 water pipes but not with just one pipe and the other feed from the manifold itself, which will allow normal water flow throughout the manifold, as original.

I made a jacket from a scrap of box section, drilled a couple of holes to allow water flow. I used an offcut of quarter inch brake hose to the adapter and 8mm for the original hose that normally gets capped off or short-circuited. Also capped the jacket and welded it on to the adapter, welded the 8mm connector and soft soldered the brake hose

Connecting Back Up

Made a gasket to suit the adapter to manifold with additional hole for coolant flow, connected the original water pipe to the hot water jacket 8mm pipe.

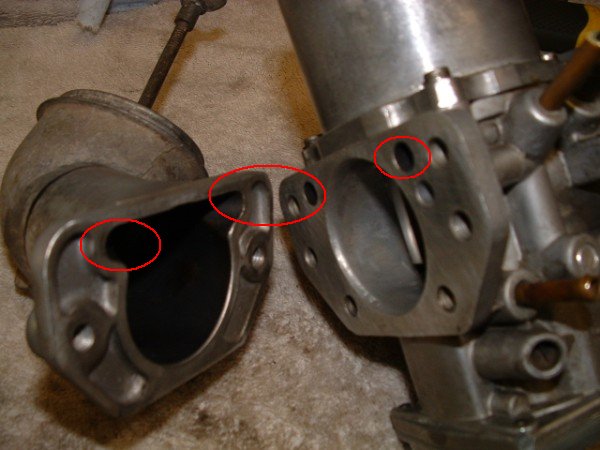

If you make your own air filter adapter you need to make 2 slots into the inlet itself to allow the piston damper to draw air. This is a must, because with out them, the damper can't rise freely. If using a normal SU air filter connector then there is no need to worry.

I've circled in red the normal air flow passages.

Bolt on the SU to the adapter with new gaskets, connect up the throttle cable and choke cable. I bought a longer throttle cable and cut it to suit. Choke is a 'one size fits all' cable from my local auto factor, cut to suit.

Connect the fuel line. I used an inline fuel filter with stepped pipe sizes as it allows easy adaptation from 6mm to 8mm fuel hose sizes as the fuel pump uses 6mm and the SU takes 8mm.

Connect a pipe from the carb to your air filter/snorkel.

I cap off the big pipe on the carb that used to take the feed from the donor cars rocker cover.

Why put dirty air into nice clean air?

I run the original pipe from the Suzuki's rocker cover into the T piece that goes down to the PCV valve and on to the original air filter.

For safety's sake, run a pipe from the float overflow to a point somewhere near the bottom of the engine, the last thing you want is petrol running over anything hot should the float ever jam open.

Top up the damper with SAE20 grade oil (that's what is recommended by Burlen).

You will need to connect up an air filter any way that you can.

I've deliberately not shown mine as each case will be different, dependant on your own particular circumstance.

Pull the choke out, fire it up and as it gets hotter, progressively put the choke in and then set the mixture!

Don't forget, turning the mixture screw IN on an SU HIF44 makes the mixture RICHER (therefore, undoing it makes it leaner!).

How does it run?

ust fine, and if you've done it right it should fire up for the first time within a few seconds.

I do need to test some more as I only fitted it up today and will also try a BDL needle as it is slightly richer than a BFM and on the test drive mine felt a little sluggish on the BFM with yellow spring.

This article was written and photographed by Nigel Head. It was originally posted on difflock and can be found HERE

![0610_4wd_01z+suzuki_samurai+group_of_suzukis[1274].jpg](/images/gallery/favourites/0610_4wd_01z+suzuki_samurai+group_of_suzukis[1274].jpg)

![fenderfrt6_SJ-1[376].jpg](/images/gallery/favourites/fenderfrt6_SJ-1[376].jpg)