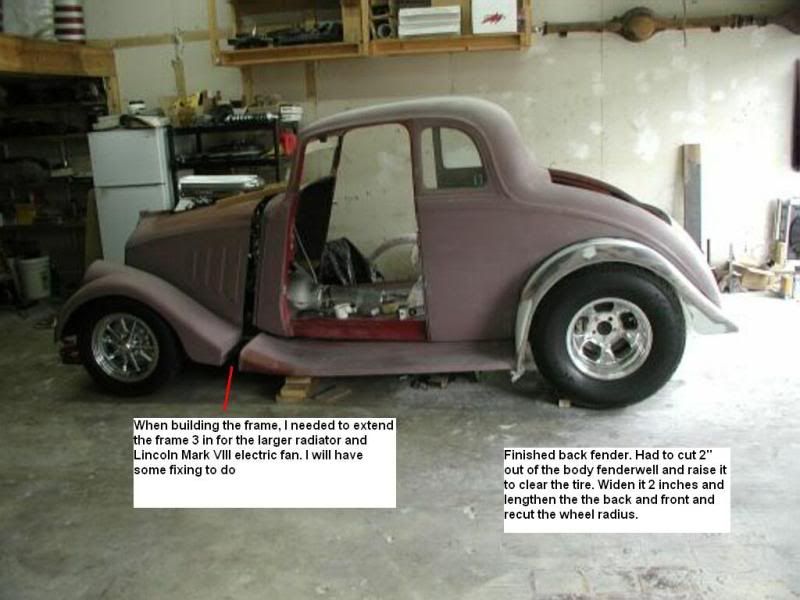

Start off with the 33 Willys that still needs to be completed.. Yes, Willys does make cars also and are a popular pick for the Hotrodders.

Start off with the frame and motor being installed. I bought the frame rails mandrel bent for this application. Added the remaining parts to make it a complete frame. This is a very complicated process and you need some type of frame fig to do a good job.

Have a rolling chassis with the motor installed

Rear view of the chassis. You will notice that there are blocks of wood for the rear shocks. I have found it much easer and cheaper to make mock up parts form wood to start with.

Have very little room for clearance between the rear frame rails and the tires. Decided to make a Watts link to take care of this issue.

Solid transmission mount pic. Decided to go this route becuse the motor mounts are also solid mount. There will also be some additional mounts added at the bell housing as well.

Body just installed to check for fitment

Side view

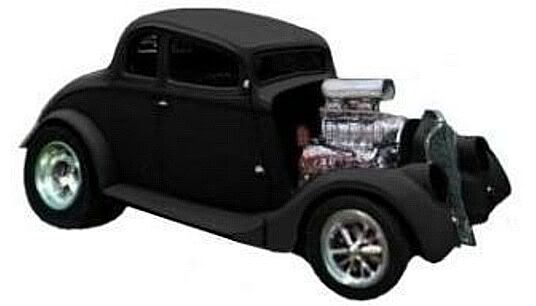

Here is a rendering that was done before starting on the build. This gives you a very good idea of what you are trying to build with no surprises at the end.

Here is the motor that has just been freshly on packed from the shipping create. Had the motor built because it seemed to be a better solution then piecing it together with all the after market components. It has been my experience that these parts generally have to have something done to them to get them to fit or work properly.

Give a short description of the motor. Blown 383 Small Block Chevy making about 800HP. Sent a video to Scott to hear the motor running. Not able to upload it because I have dial up sorry. If Scott decides to check in he can let you know what 800HP sounds like.

Just as everything else with a custom build there needed to be a set of headers made. This was the 1st time for me attempting a set of headers. This is what the US drivers side looks like.

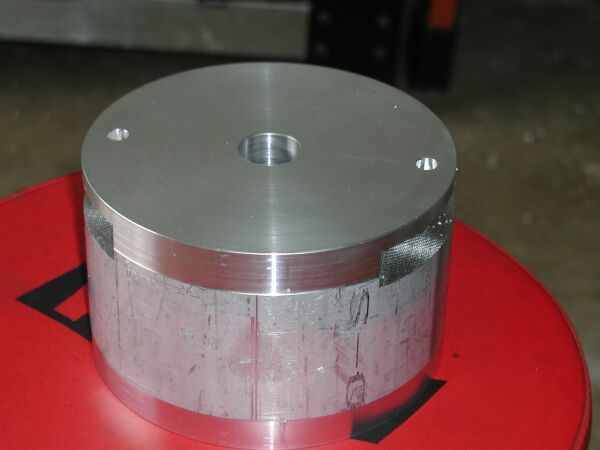

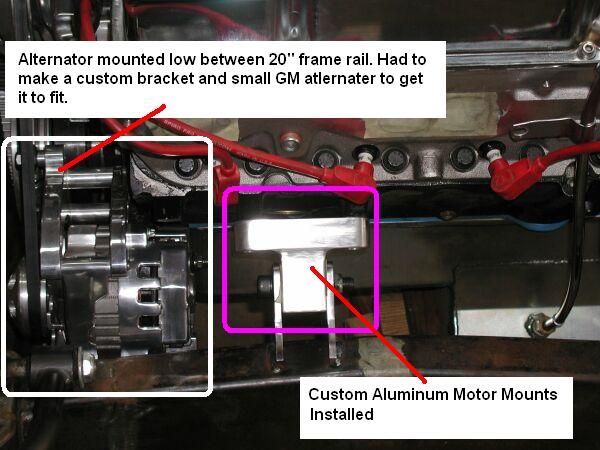

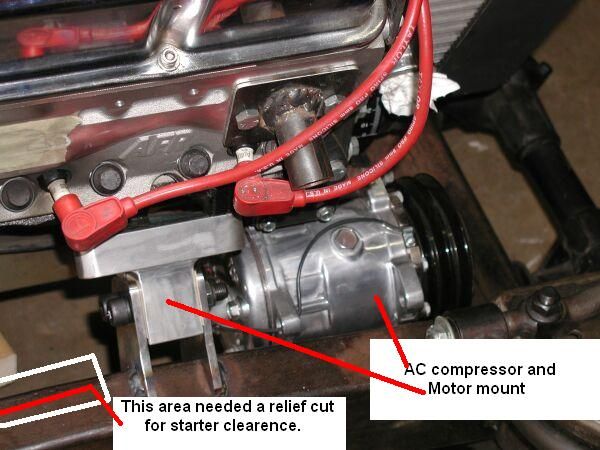

There also needed to be a set of motor mounts made. Decided to start with a block of T6061 aluminum.

Here is one completed and the other partially done to give you an idea of the process.

Just wanted to say this about the next pic. Been machining for a long time but every once in a while I get bit. This was the worst one ever. This happened when checking a blend area with my finger with the cutter running.

This is the 1st thing they teach you not to do when you go to school. I knew better when I did it and will never do it again. This injury took about a year to heal up and a couple of more years for it to feel normal and the nail to finally grow back.

The Willys was bought all together but was a mess. Drove it a couple of times an decided it was time for an overhaul. Hadn’t planned in going as far as I did in the beginning. Always wanted a set of the spoke wheels for the front this lead to all the major changes and new frame.

As I mentioned the car was in bad shape and when I cut the front frame to shorten the width to get the wheels to fit under the body. The frame was sprung leading to the new frame build. Just have to take things as they come when you start modifying and always have a plan B.

I also bought a set of Wilwood spindles and brakes setup for the front. The hubs ended up being a bit too wide to get the wheels under the body. This lead to me making my own spindle hubs and brake brackets.

Here are some pics of the new spindle and a few pics of them being machined.

Completed spindle hub bolted to the Wilwood rotor. Used the front screw in bearing cover that came with the original kit so I didn’t have to make one.

Here are the finished hub portion of the spindle

Front Side

Back Side

Here is a few pics of the mounting flange being machined and finished.

One of the several machining processes.

Finished hub mounting flange back side view bolted to the hub.

Finished hub mounting flange by itself.

That’s it for the Willys just wanted to show some of the high lights of the build.

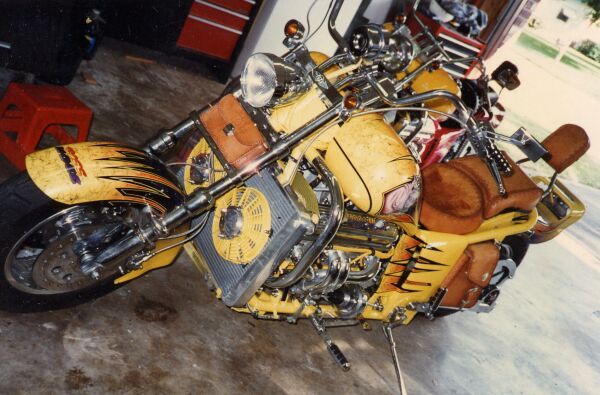

Here was something that I decided to pursue when the place that I worked at for 15 years decided to close down and move out of state.

This is called a Boss Hoss. It is a kit bike that you would purchase and build for customers to their hearts desire. Did the for several years and built 40 of them. A few custom ones also put the dealers bike together as well.

They consist of is a chevy ZZ3 and later ZZ4 motor on 2 wheels and a frame. Very fast with 355 HP on 2 wheels 0 to 60 in 2.9 seconds. The pics that I will show are of a couple of the custom bikes that I built. One winning the Best of Show at Daytona Beach Rats Hole Contest.

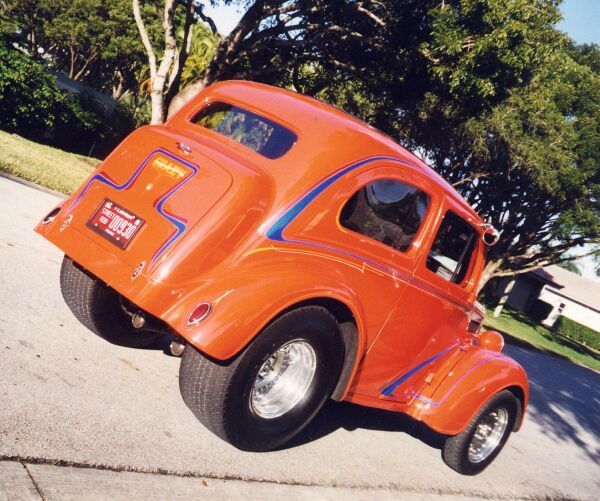

Here is a car that I had wanted since I was 16 years old when I saw one in my home town pull a wheelie on the street in front of a group of us. When I got much older and starting to get out of the motor cycle building I finally found one after lookinf for a couple of years for a good one.

It is a 1948 Anglia. I’m sure that you have seen these in the UK perhaps not like this one.

Short description 350 small block Chevy modified, single 4 barrel carb, GM shortened rear axle with 410 gears, Anglia front suspension. Very Fast the usual theme in all this.

Here is the Back side view, tends to resemble a phone booth.

All these vehicles are street legal, I have driven all of them except the Willys that still needs completed. This will be done after the Zuk on 38’s is finished.

If you haven’t stopped in to the Zuk on 38’s thread yet here is the link. There are more unique things being done on the thread.

Link

http://forum.suzukiclubuk.co.uk/vi ... adb437cb6/

Hope you enjoy the pics.

Terry