I’m going to include this info in this thread.

Scott has also posted it in your DIY section.

This info seems to be very well appreciated on the Zu and ZK and was moved to sticky’s shortly after posting. I hope that you get something out of it as well.

The trans is not talked about too much and being in the process of rebuilding the one going in this build. Thought it would be a good time to share a few tips and tools that were picked up on in a couple of pervious rebuilds.

Reference Rebuild Info:

This is a good step by step and pics

http://www.geerdijk.com/files/suzuki/tranny_rebuild.pdf

The FSM will be needed for a few things that were not covered.

This is my minimum parts list and parts # from LROR.

1----STM-ISR-----------Samurai Transmission Front Input Housing Bearing Retainer

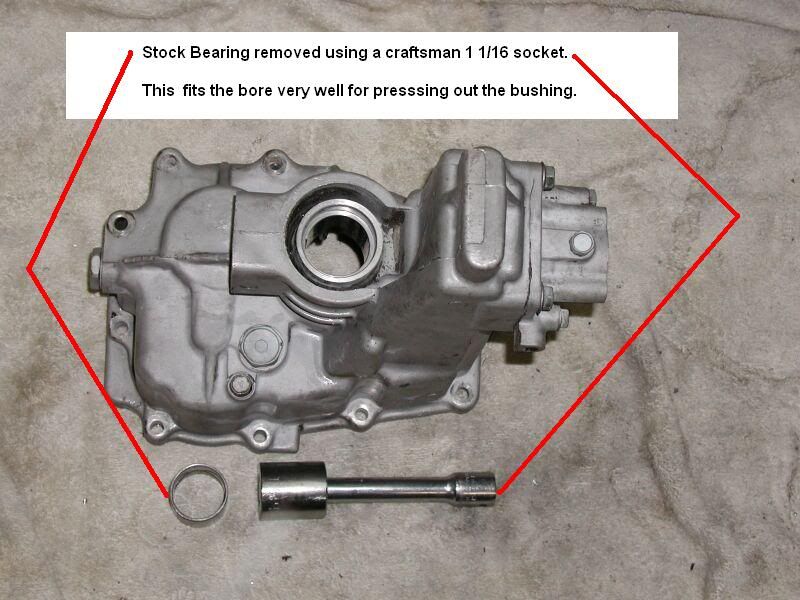

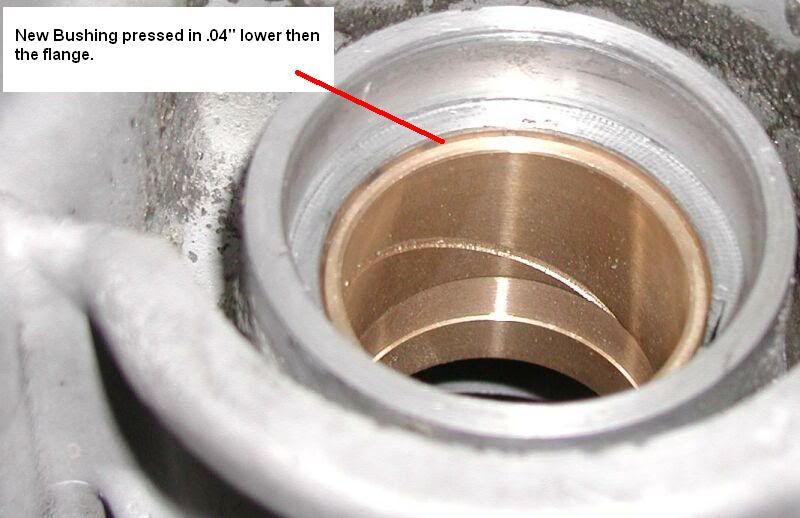

2----STM-CRSB--------Samurai Clutch Release Shaft (throwout) Bushing

1----STM-TNB----------Samurai Transmission Needle Bearings

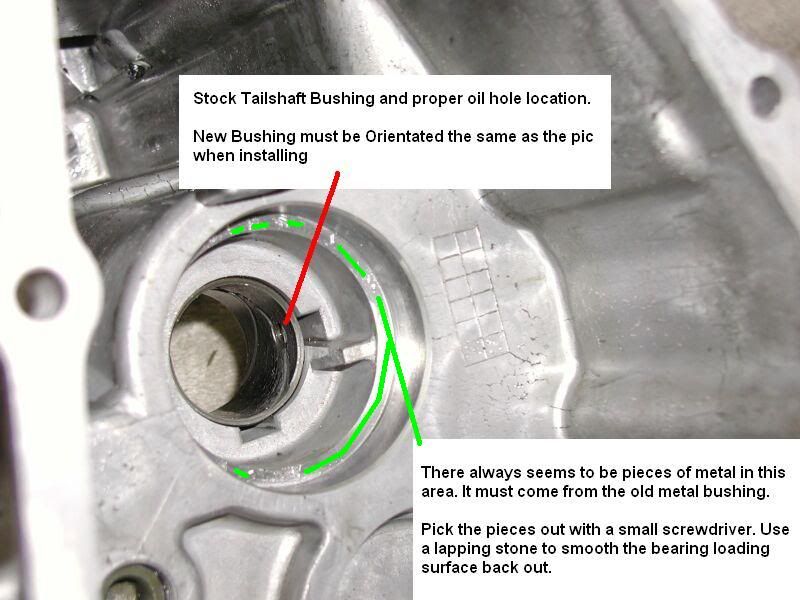

1----STM-RRTB--------Suzuki Samurai Transmission Tail Shaft Bushing

1----STM-UTM---------Unbreakable Rear Transmission Mount

1----SDT-TBS----------Samurai Transmission Shifter Bolt 86-89

1----STM-TIP-----------Samurai Timing Inspection Plug

1----SDT-TMBN--------Samurai Nylatron Transmission Shifter Bushing

1----STM-RKS----------Samurai Transmission Rebuild Kit w/ Syncros And Silicone

1----STM-CRSOS-----Clutch Release Shaft (Throwout) Oil Seal

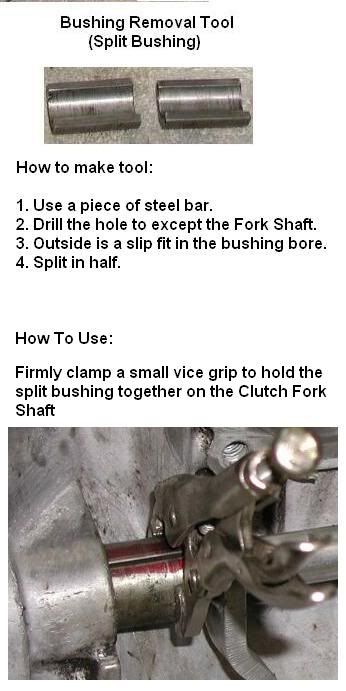

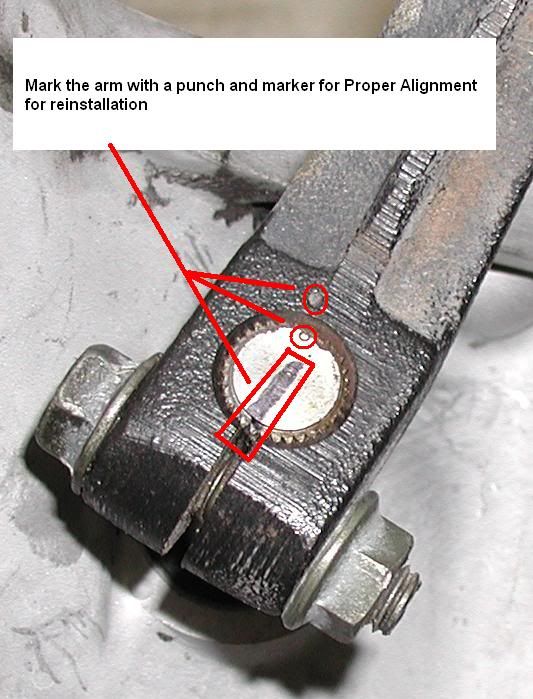

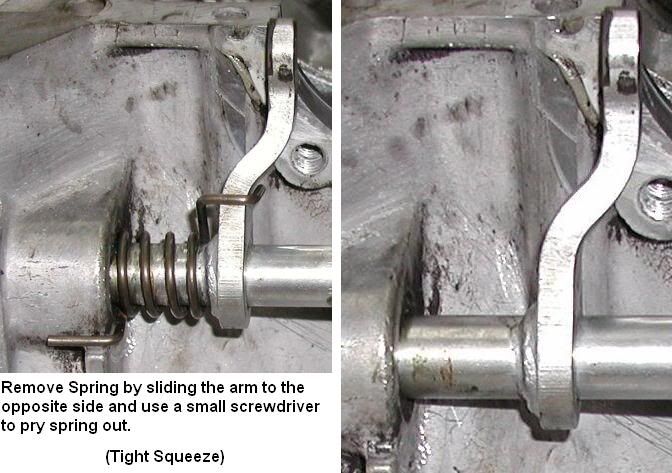

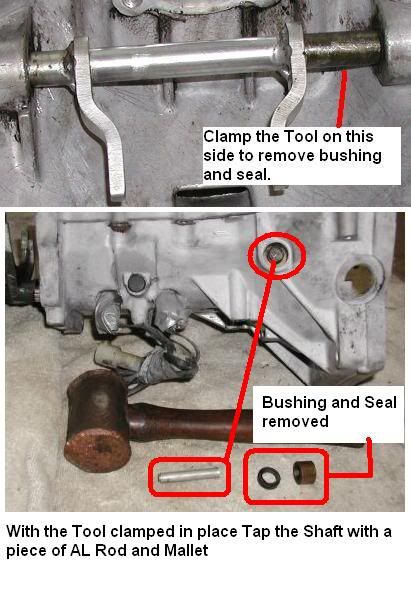

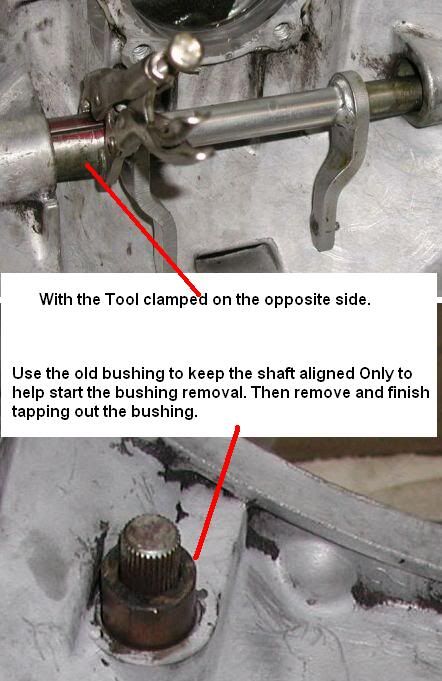

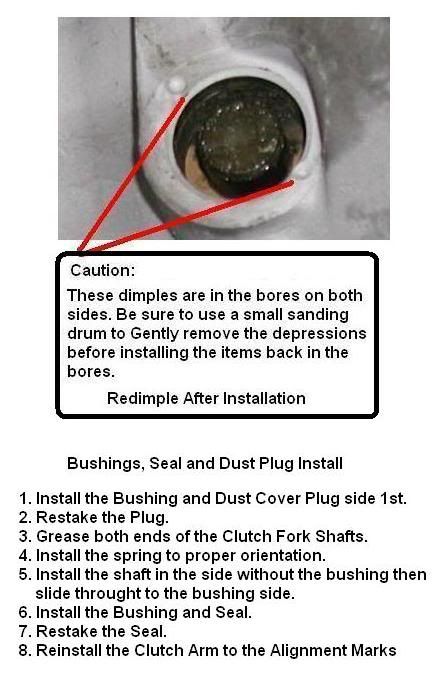

There are a few grey areas I will try and shed some light on.

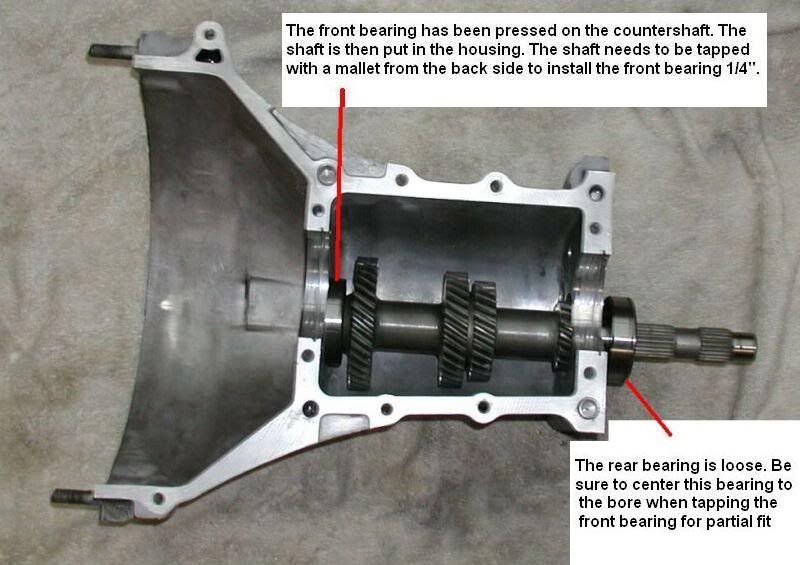

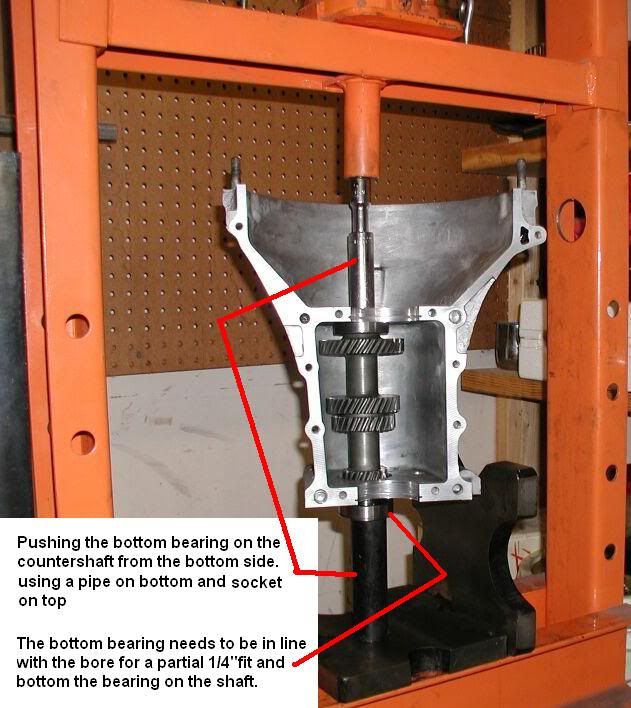

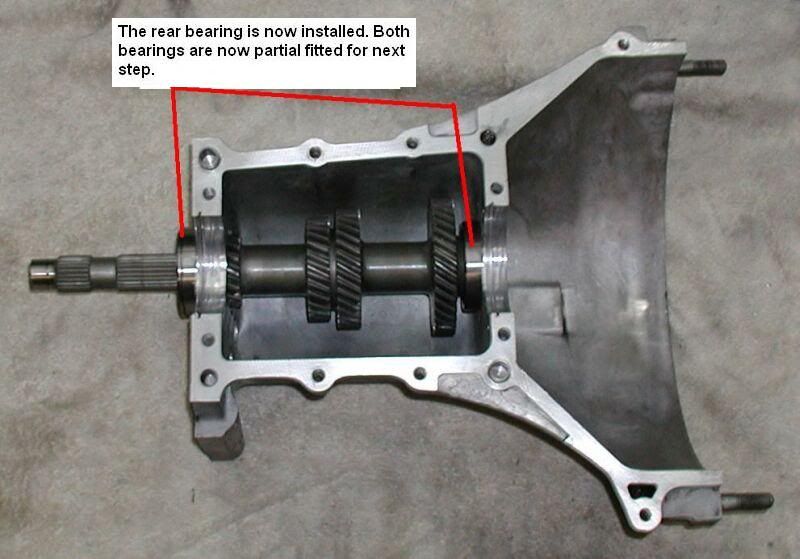

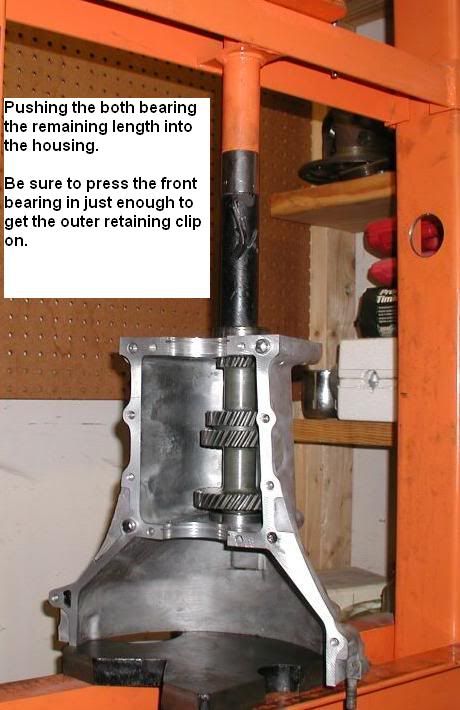

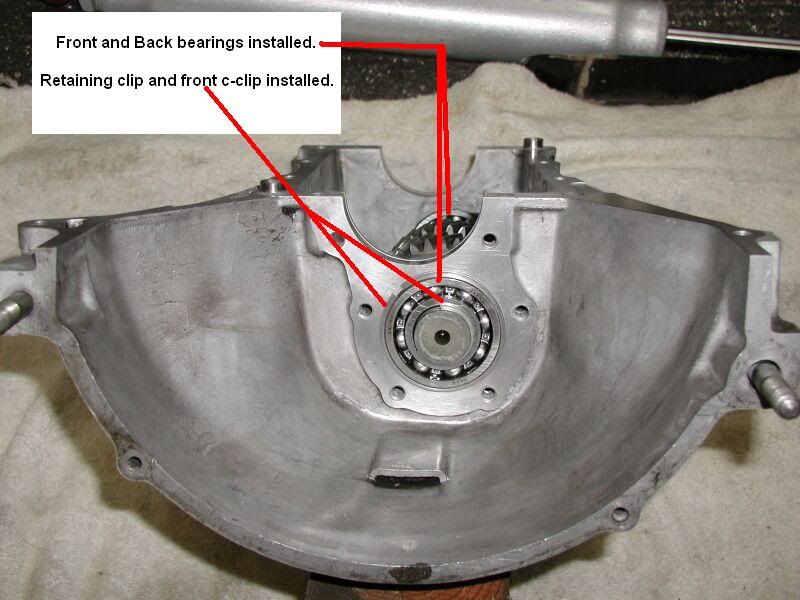

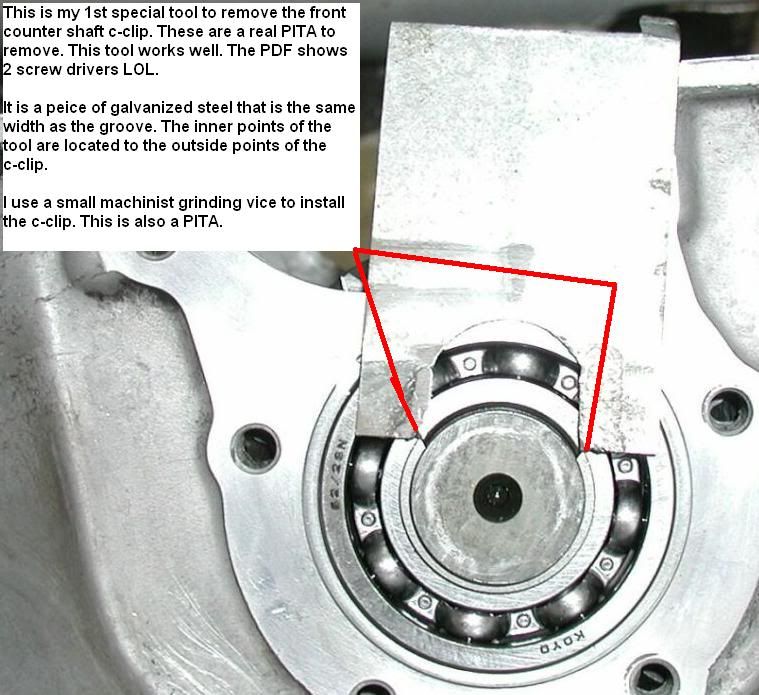

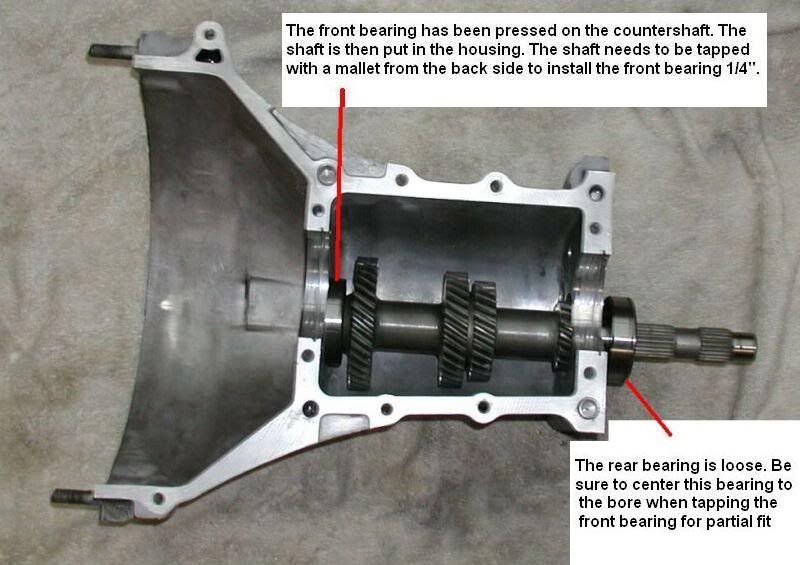

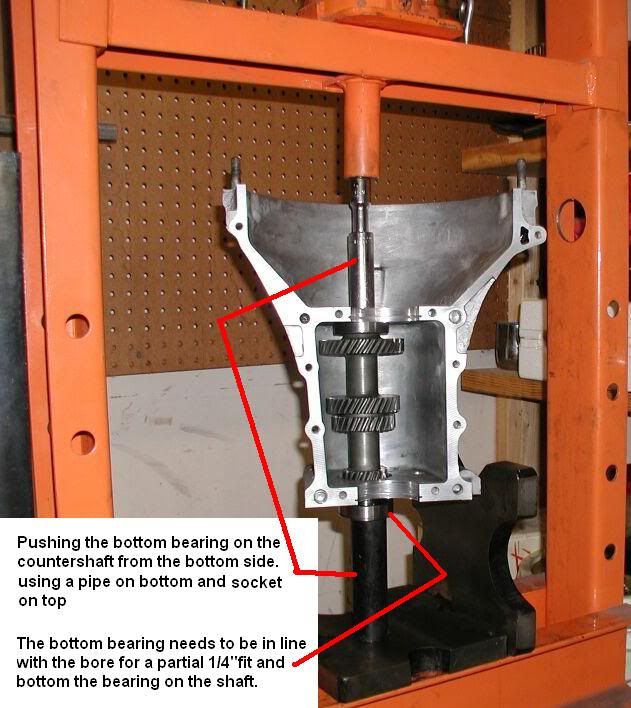

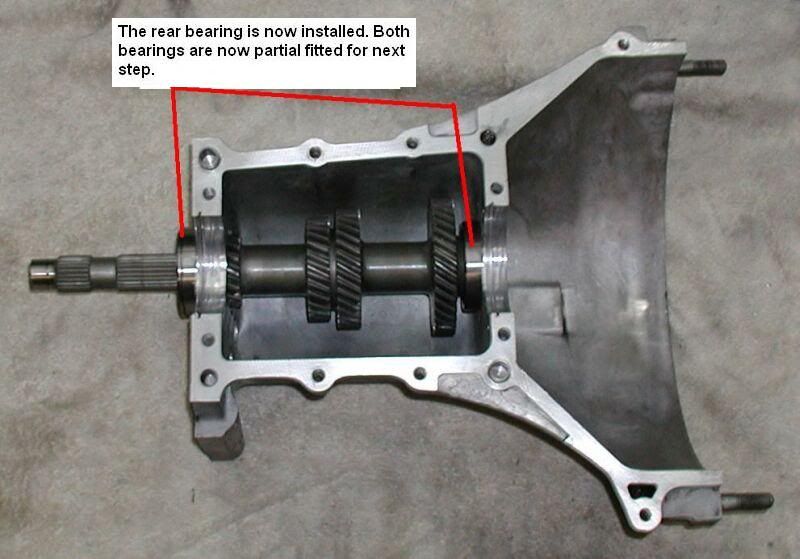

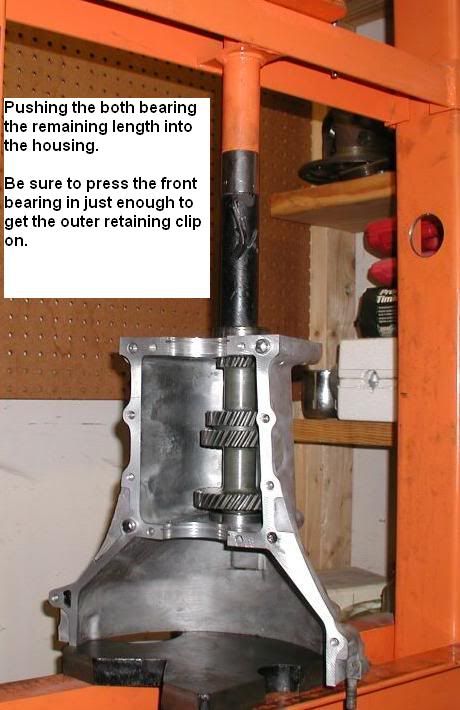

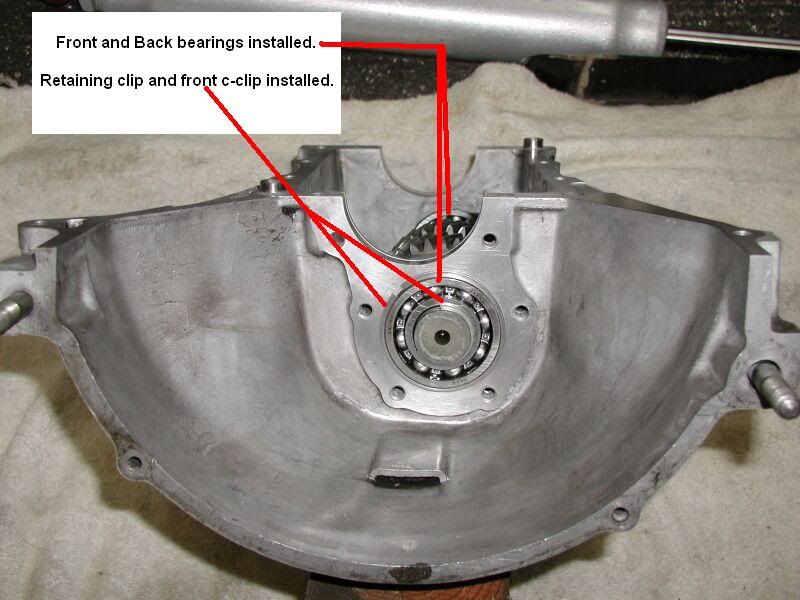

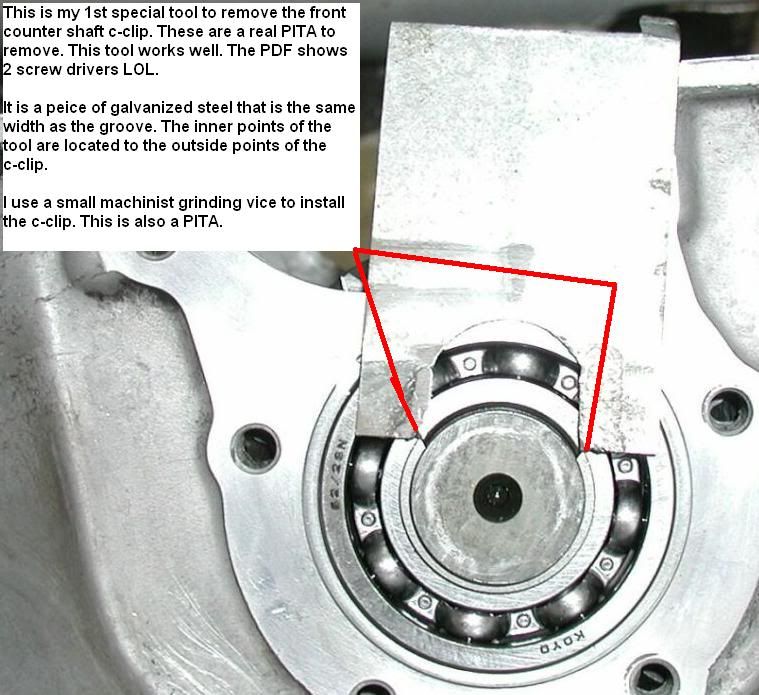

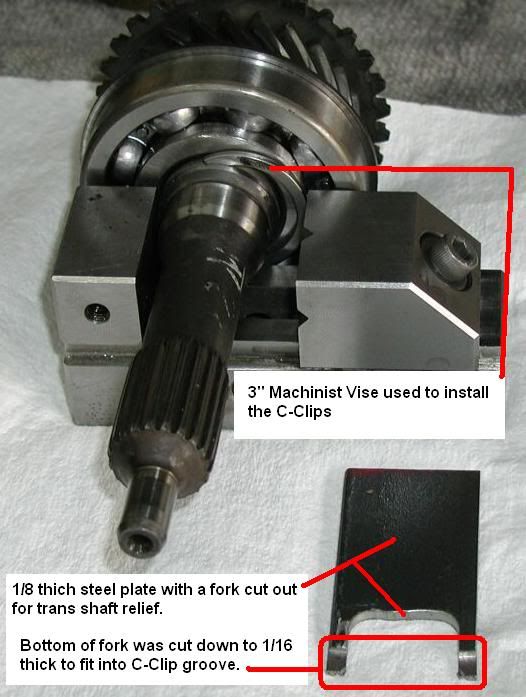

The countershaft installation is one of those grey areas. This is the procedure that works well with a press, mallet, couple of sockets and a piece of pipe.

Pics are marked in detail