Re: Zuk on 38's

Posted: Fri Feb 24, 2012 2:35 am

I will keep the Tip Theme continuing

Here are a couple more tips when rebuilding the motor:

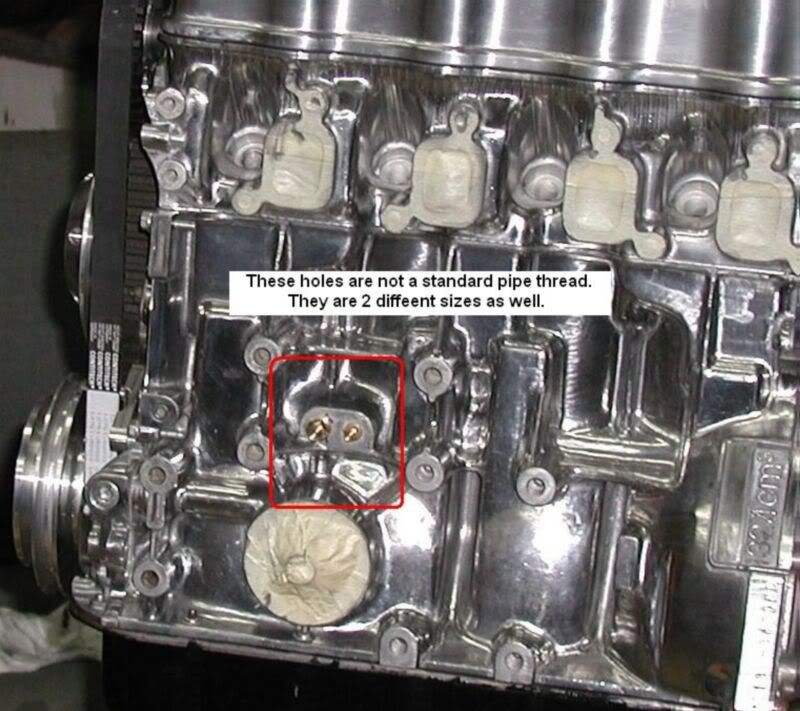

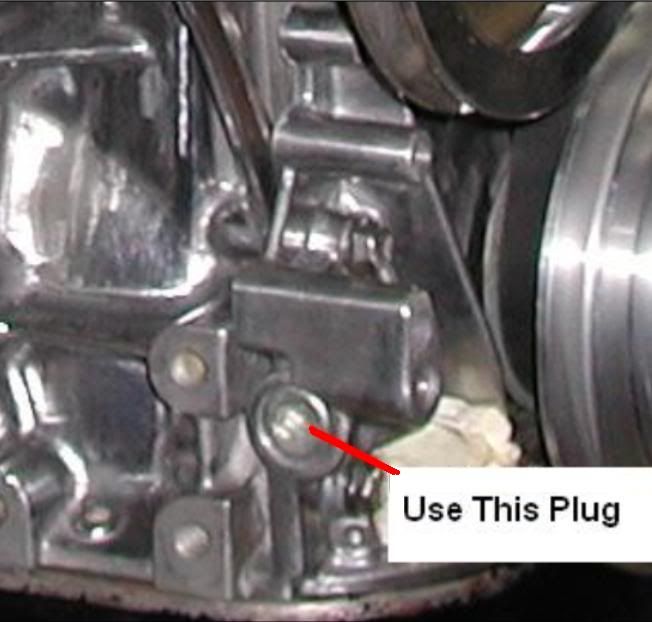

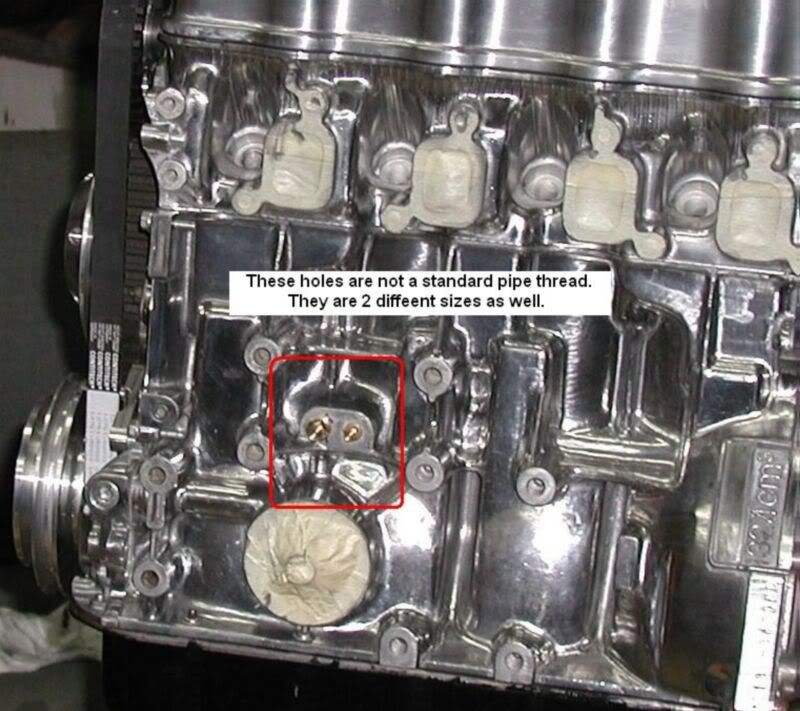

Oil Pressure Fittings.

I thought that I would add this because it really isn't covered much. The oil pressure fittings on top of the oil filter are NOT standard pipe threads. I have read on several posts that it is OK to just thread your accessory oil line in and there is no problem.

CAUTION:

You are asking for trouble if it decides to let go. You are just cross threading it in and the only thing that is really holding it in is the taper.

If you are rebuilding the motor it would be a good time to do this. I would not advise doing it with the motor in the Zuk because of the metal shavings that will get in the motor.

I wanted to see how many chips would actually get in there while I was doing it on the engine stand with the motor positioned like in the pic but facing the floor. This is the hard way but I wanted the chips to fall out by gravity also. I used grease on the tap. I also made an extension for the vacuum and sucked out everything I thought. Well, that long oil passage that runs from end to end still had some chips in it. I had to use a bore brush to get them out.

I would only suggest re tapping them at rebuild.

If you are planning on an oil pressure line. I read that there are adapters from the stock thread to a NPT. I haven't got any PN's or have I tried to find any

Here are a couple more tips when rebuilding the motor:

Oil Pressure Fittings.

I thought that I would add this because it really isn't covered much. The oil pressure fittings on top of the oil filter are NOT standard pipe threads. I have read on several posts that it is OK to just thread your accessory oil line in and there is no problem.

CAUTION:

You are asking for trouble if it decides to let go. You are just cross threading it in and the only thing that is really holding it in is the taper.

If you are rebuilding the motor it would be a good time to do this. I would not advise doing it with the motor in the Zuk because of the metal shavings that will get in the motor.

I wanted to see how many chips would actually get in there while I was doing it on the engine stand with the motor positioned like in the pic but facing the floor. This is the hard way but I wanted the chips to fall out by gravity also. I used grease on the tap. I also made an extension for the vacuum and sucked out everything I thought. Well, that long oil passage that runs from end to end still had some chips in it. I had to use a bore brush to get them out.

I would only suggest re tapping them at rebuild.

If you are planning on an oil pressure line. I read that there are adapters from the stock thread to a NPT. I haven't got any PN's or have I tried to find any