Bad Gas Solution (Sunoco Premium was being used)

Going to switch to REC90 to eliminate the ethanol issues

Built my motor about 1 ½ years ago and start it up weekly with good gas. Have a very simple gas tank system set up consisting of:

New 2.5 gallon plastic tank

New Fuel pump and fittings

New fuel and return lines

New anus return filter

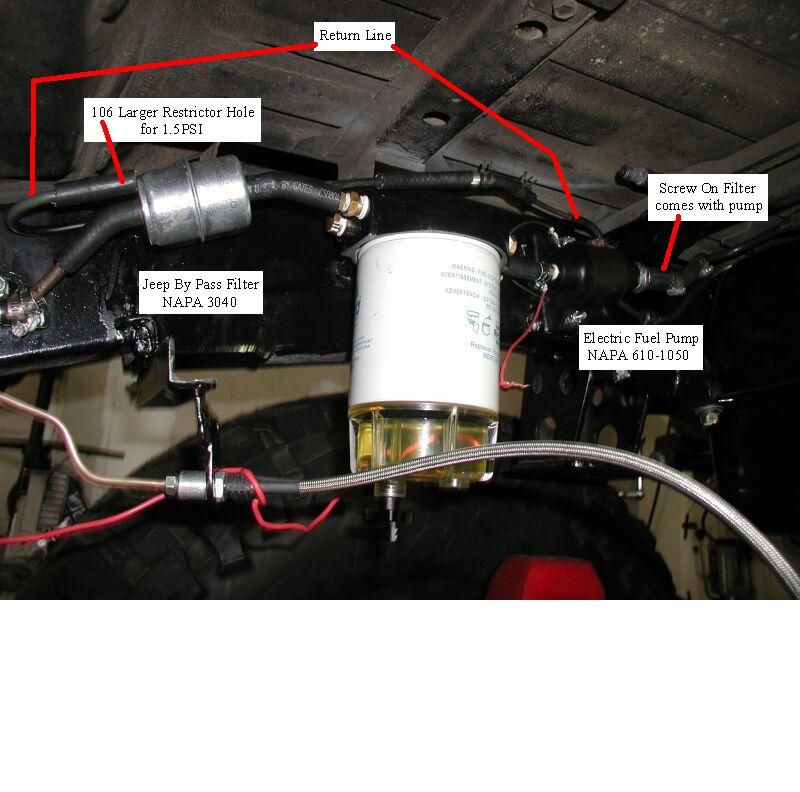

This worked out well for about 4 months until the fuel pump quit. Decided to use a Napa electric fuel pump this time and have not had any issues.

Been having issues idle issues with the Quad carbs the past 6 months to where it really didn’t want to run well any more. Pulled the carbs down and noticed all the brass jetting was rusty. This surprised me since the carbs were rebuilt and new jets were installed previously.

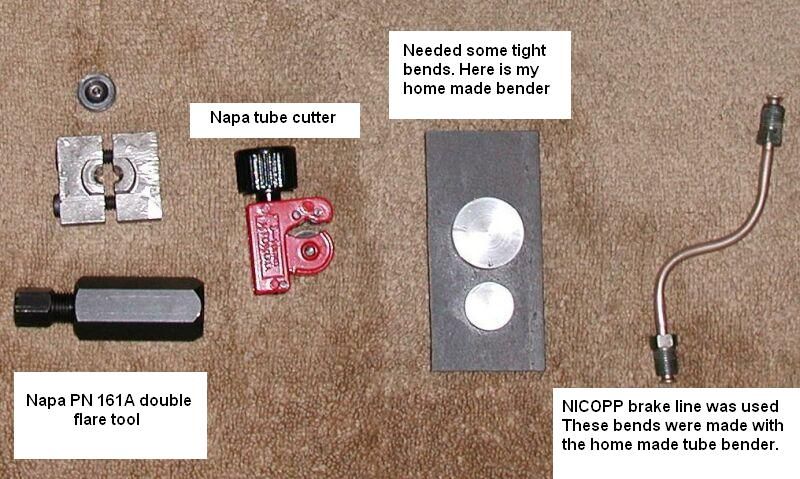

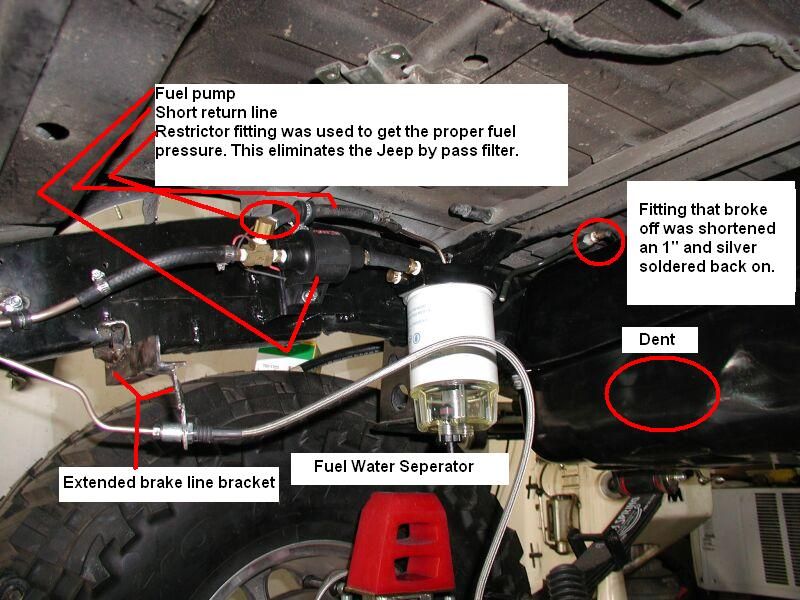

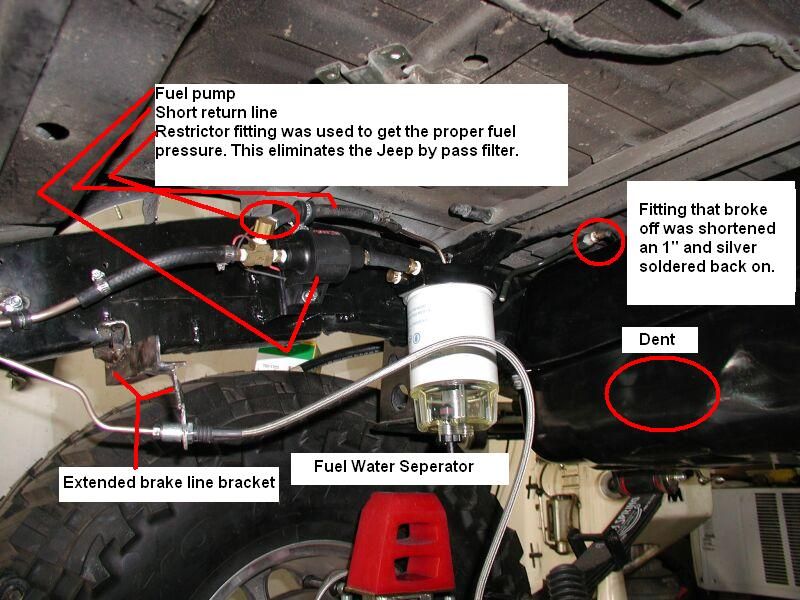

To try and resolve this problem decided to use a fuel water separator, new tank from Rock Auto, new Nicopp 5/16 fuel line and a new Napa fuel pump.

BTW: not sure if I would recommend the Rock Auto gas tank. It was not double boxed and had no packing of any sort to prevent damage. Had 1 corner that was damaged where it mounts and a hand sized dent on the inner panel near the axle. There was also a vacuum line missing going to the plastic bottle by the gas cap. The fuel feed line was also an 1” longer and when the line metal line was screwed back on the fitting had broken loose. Since the fitting broke off this was a good time to shorten that tube an 1” and had it silver soldered back on. There is not a bottom drain either.

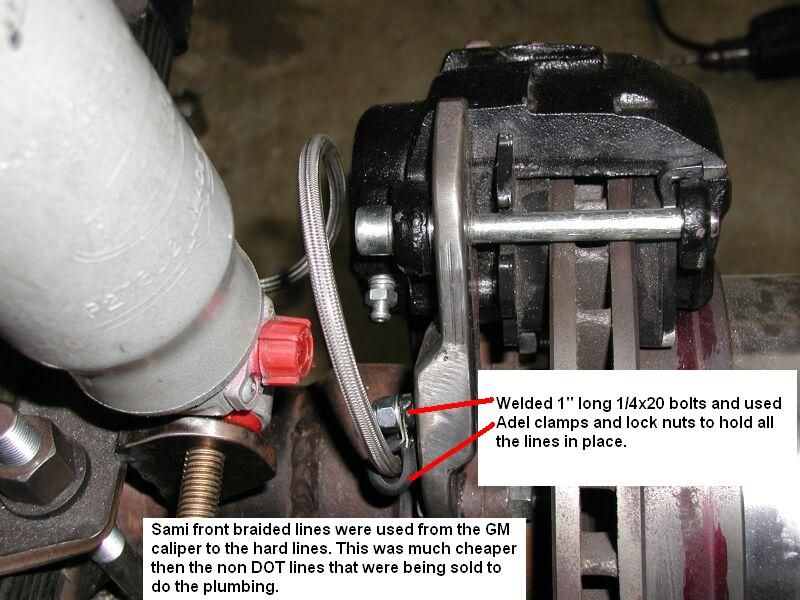

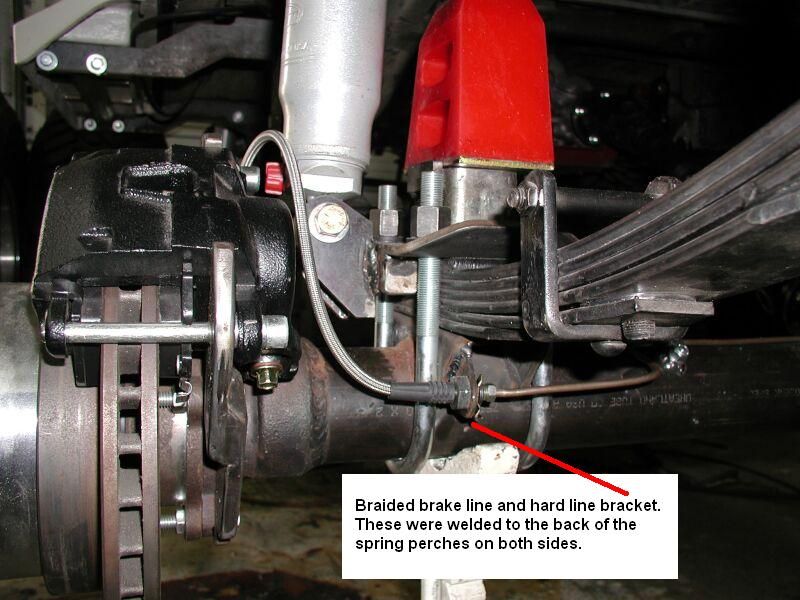

Here is what the new systems looks like and had to be redone since I was going the standard method and already made the mounting. Also had to move the rear axle brake line mount over to clear the new filter.

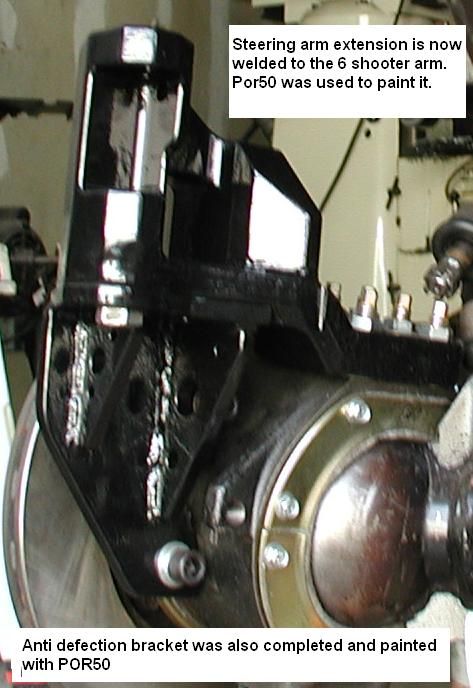

You may have noticed that the frame rails have been stripped and painted with POR15 along with many other parts. Have ti running of the gas tank in the Rig now. Getting there.