Extended spring perches?

- NylonAdmiral

- Winching along now

- Posts: 521

- Joined: Wed Apr 03, 2013 8:39 pm

- Location: Devizes, Wiltshire

- Contact:

Re: Extended spring perches?

Yes what you're saying is correct, the axle moves in an arc around the fixed locus that is the forward spring eyes. The only problem is that the axles position on this radius changes as the springs compress so it's not a fixed radius as such. When the springs compress and become "flatter", the axle itself is moved further from the spring eye and therefore the radius on it's arc of travel is increased. This "variable radius" is why people use a shackle.

Like we discussed though, on standard or standard-ish springs this is only a very small issue but it does bring you back to the same trade off position that we started with and I think, geometry wise, it is mathematically inescapable but I too am happy to be corrected.

To be honest I wouldn't think it were much of an issue on non-standard springs unless they were really soft and really curved.

Like we discussed though, on standard or standard-ish springs this is only a very small issue but it does bring you back to the same trade off position that we started with and I think, geometry wise, it is mathematically inescapable but I too am happy to be corrected.

To be honest I wouldn't think it were much of an issue on non-standard springs unless they were really soft and really curved.

1.6 16v, Rock Lobster, PAS, Muddyzook rear disc conversion, coated in Raptor, 33in x 10.5, heated seats, lovingly restored by Scottie!

- d_r_1989

- Winching along now

- Posts: 583

- Joined: Tue Jul 08, 2014 1:49 pm

- Location: Halifax west Yorkshire

Re: Extended spring perches?

I think I'm going to copy your design if im honest nylon. You have first hand knowledge of it making a difference so I'm gunna go with yours!

Re: Extended spring perches?

It goes into a bit of detail about setting up the geometry in the link I posted. As long as your springs are really have loads of arch you can set it up so there is such a minimal effect on the pinion angle during flex that I wouldn't worry about it. If I was to build one I probably wouldn't use the extra shackle like Adams.

You have to remember that as one wheel compresses the other droops so you actually get a bit of roll steer and the centre of the axle doesn't move forwards or backwards as much as it does at the wheels.

You have to remember that as one wheel compresses the other droops so you actually get a bit of roll steer and the centre of the axle doesn't move forwards or backwards as much as it does at the wheels.

-

Anton

- I spend far too much time on here

- Posts: 3862

- Joined: Tue Jan 12, 2010 12:12 pm

- Location: London

Re: Extended spring perches?

Hmmm, yes - that makes perfect sense, actually. The distance from eye to axle housing will get greater as the spring flattens, then reduce again if the spring inverts, or have I misunderstood?NylonAdmiral wrote:When the springs compress and become "flatter", the axle itself is moved further from the spring eye and therefore the radius on it's arc of travel is increased. This "variable radius" is why people use a shackle.

All good points!ScottieJ wrote:It goes into a bit of detail about setting up the geometry in the link I posted. As long as your springs are really have loads of arch you can set it up so there is such a minimal effect on the pinion angle during flex that I wouldn't worry about it. If I was to build one I probably wouldn't use the extra shackle like Adams.

You have to remember that as one wheel compresses the other droops so you actually get a bit of roll steer and the centre of the axle doesn't move forwards or backwards as much as it does at the wheels.

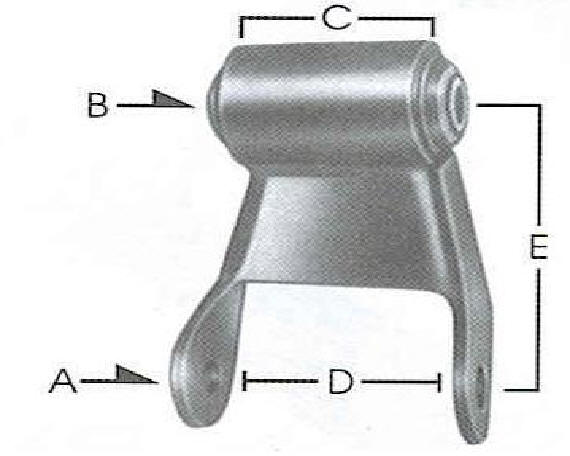

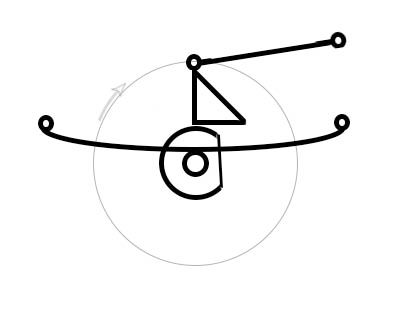

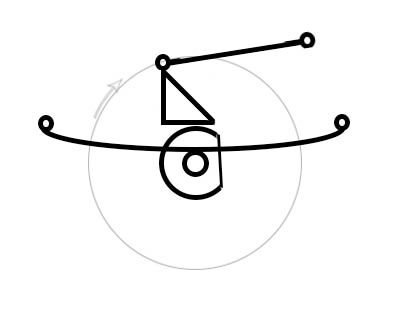

I was thinking of making it shackle-less, and if that's a problem, I can make something like this (but shorter):

Then I have the option of running shackled, or shackle-less.

Or I could do something a bit like this:

That upside down "U" shaped bit of metal representing the chassis mount for the upper link. With a couple of thick washers, that would also work imo. In my head I don't need a shackle, but I see no reason not to plan ahead in case that's wrong.

1985 SJ413VX (SJ50V) with SPOA, rear disc brakes, 31x10.5R15 Kaiman Malatesta tyres, an MOT and a lot left to do!

My: Build thread ● To-do list ● Pay and Play map

My: Build thread ● To-do list ● Pay and Play map

- NylonAdmiral

- Winching along now

- Posts: 521

- Joined: Wed Apr 03, 2013 8:39 pm

- Location: Devizes, Wiltshire

- Contact:

Re: Extended spring perches?

Yeah, that's correct.Anton wrote:Hmmm, yes - that makes perfect sense, actually. The distance from eye to axle housing will get greater as the spring flattens, then reduce again if the spring inverts, or have I misunderstood?

Well I think Matt also has first hand experience of not using a shackle and he had good feedback earlier in the thread too. I can't take any credit for the design but if you have any questions I can help with let me know.d_r_1989 wrote:I think I'm going to copy your design if im honest nylon. You have first hand knowledge of it making a difference so I'm gunna go with yours!

Yeah exactly. Like I've said, the cons each way are pretty close to being negligible. It depends on what you think is right for you and your vehicle. If I had another SPOA truck with loads of lift and really curved springs I'd definitely use a shackle again. Like you say Scottie, if I had normal-ish springs, and moderate lift, I'd be tempted to leave the shackle out too.ScottieJ wrote:As long as your springs are really have loads of arch you can set it up so there is such a minimal effect on the pinion angle during flex that I wouldn't worry about it... If I was to build one I probably wouldn't use the extra shackle like Adams

Anton, if you're interested in the geometry, the other thing to look at is the mounting points of the tether. The more parallel the tether is to the springs, the more the axle will will move in a sort of up/down, reciprocating motion. The closer you have the leading edge of the tether to the locus of the spring eye, the more you'll get a sort of oscilating motion. These are slightly exaggerated examples for illustrative purposes but they highlight how the tether position is worth thinking about.

I personally think that the reciprocating motion is what you want to aim for.

1.6 16v, Rock Lobster, PAS, Muddyzook rear disc conversion, coated in Raptor, 33in x 10.5, heated seats, lovingly restored by Scottie!

-

Anton

- I spend far too much time on here

- Posts: 3862

- Joined: Tue Jan 12, 2010 12:12 pm

- Location: London

Re: Extended spring perches?

Thanks, Admiral! That confirms that the things floating around in my noggin aren't nonsense, and the design I'm thinking of is sound. Reassuring!

Gonna read the jeepaholics article again just to make sure. For example, I'm trying to work out why he thinks that you have to put the upright section of the triangulated bit directly above the axle's centreline - not saying he's wrong, just want to work out why you can't put the upright behind the axle centreline and the other end of the triangle in front of it as in my brain that would give you more leverage. What are your guys thinking on that one?

Gonna read the jeepaholics article again just to make sure. For example, I'm trying to work out why he thinks that you have to put the upright section of the triangulated bit directly above the axle's centreline - not saying he's wrong, just want to work out why you can't put the upright behind the axle centreline and the other end of the triangle in front of it as in my brain that would give you more leverage. What are your guys thinking on that one?

1985 SJ413VX (SJ50V) with SPOA, rear disc brakes, 31x10.5R15 Kaiman Malatesta tyres, an MOT and a lot left to do!

My: Build thread ● To-do list ● Pay and Play map

My: Build thread ● To-do list ● Pay and Play map

- NylonAdmiral

- Winching along now

- Posts: 521

- Joined: Wed Apr 03, 2013 8:39 pm

- Location: Devizes, Wiltshire

- Contact:

Re: Extended spring perches?

With stuff like that, the easiest thing to do is get a piece of paper, a couple of pins and a couple of bits of wool. Use one piece of wool as the spring, the other as the tether and pin one end of each. Use something like a little piece of card to join the other two ends. You can then play with how lengths and mounting points effect the orientation of the axle as it moves. It's not exactly a precise science but it will give you a scaleable idea of the design you want to aim for.

Plus it'll give you a nostalgic trip back to arts and crafts lessons at primary school.

Can you draw a picture of what you're describing Anton?

Plus it'll give you a nostalgic trip back to arts and crafts lessons at primary school.

Can you draw a picture of what you're describing Anton?

1.6 16v, Rock Lobster, PAS, Muddyzook rear disc conversion, coated in Raptor, 33in x 10.5, heated seats, lovingly restored by Scottie!

-

Anton

- I spend far too much time on here

- Posts: 3862

- Joined: Tue Jan 12, 2010 12:12 pm

- Location: London

Re: Extended spring perches?

I can try!NylonAdmiral wrote:Can you draw a picture of what you're describing Anton?

jeepaholics wrote:STEP 5 - BUILD THE A-FRAME

Tack-weld everything into place in order to correctly position the a-frame. The rear bar should be vertical and as close to directly above the axle tube as possible. This will maximize it's ability to do its job!

I don't see why it has to be as close to directly above the axle as possible. Moving it back slightly will increase the radius it works at, increasing it's leverage

Now, it's subtle, but that circle of motion has gotten bigger, by increasing the distance between the centre of the axle and the top eye. That's going to mean it has to move further for every degree of rotation in the axle, and thus it should stop axle wrap a bit more effectively, shouldn't it?

If the pics I just made were to scale, then in that example I increased the circumfrence of the eye's rotational radius by about 5%. Moving it more would increase the distance a bit more. But also, torque would move up through that shaft in a more perpendicular motion, whereas with it directly above the axle, it's trying to bend that shaft.

I don't suppose it matters that much as it's triangulated, but it just bugged me. Why does he say it has to be directly above the axle tube? I'm not sure I agree, but I'm a layman. There's a lot I don't know!

1985 SJ413VX (SJ50V) with SPOA, rear disc brakes, 31x10.5R15 Kaiman Malatesta tyres, an MOT and a lot left to do!

My: Build thread ● To-do list ● Pay and Play map

My: Build thread ● To-do list ● Pay and Play map

- d_r_1989

- Winching along now

- Posts: 583

- Joined: Tue Jul 08, 2014 1:49 pm

- Location: Halifax west Yorkshire

Re: Extended spring perches?

Gunna have a try at making this in the next few weekends. Hopefully make up for the traction Iv lost from removing my lockright. Nylon admiral I hope your available for loads of questions! Ha