So, I don't have a welder myself

but, I can use my bosses welder

the story, however, is that his mig

is set up with 0.9mm wire, and I am not sure if this is too big to weld panel steel. there is some 0.6mm wire and a tip for it, but I've been told i need to put in 0.6mm feeder rollers as well. Is this true, and are these feeder rollers expensive to put in?

on a different note, could i just weld it with 0.9mm wire?

any help is greatly apreciated guys

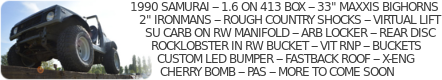

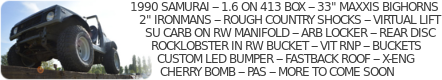

It's not a question of how much you spend on your suzuki, but when your money will run out